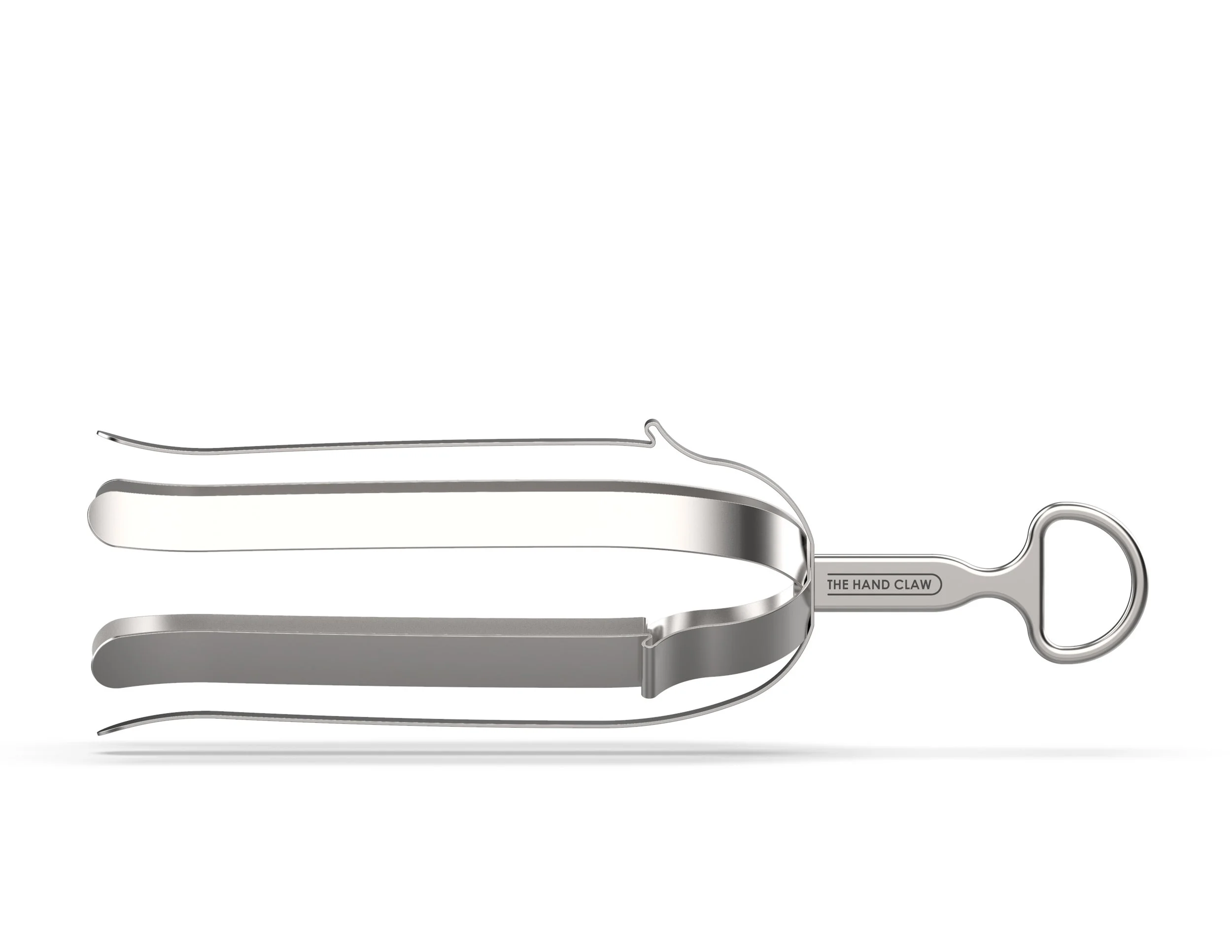

Splint Setter

A young orthopedic doctor approached me with a problem. Stretching the pre-cast sock onto an already broken arm proves to be difficult for the doctor, and painful for the patient. She had built a tool that helped her with the process, but it was a one-off prototype that didn’t look like a medical device and still needed some performance updates. We met with her and were able to fully understand what this product needed to accomplish before sending a few different concept options.

Concept Developement

Prototype Testing

This is the initial working prototype created by the orthopedic doctor. She uses it daily and even made some for coworkers to use. We know this works, now the task is to understand its working features, and create a manufacturable design with materials that can be autoclaved.

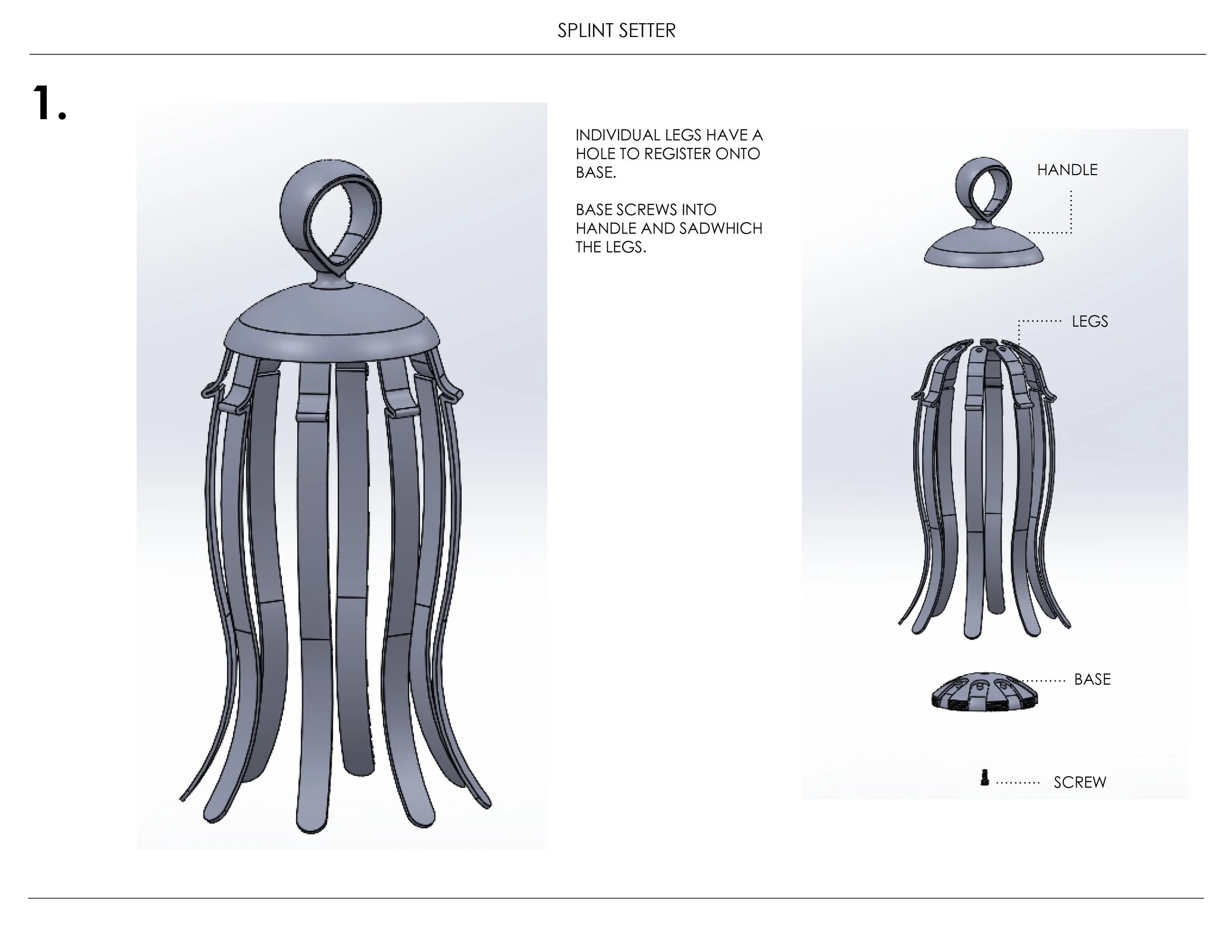

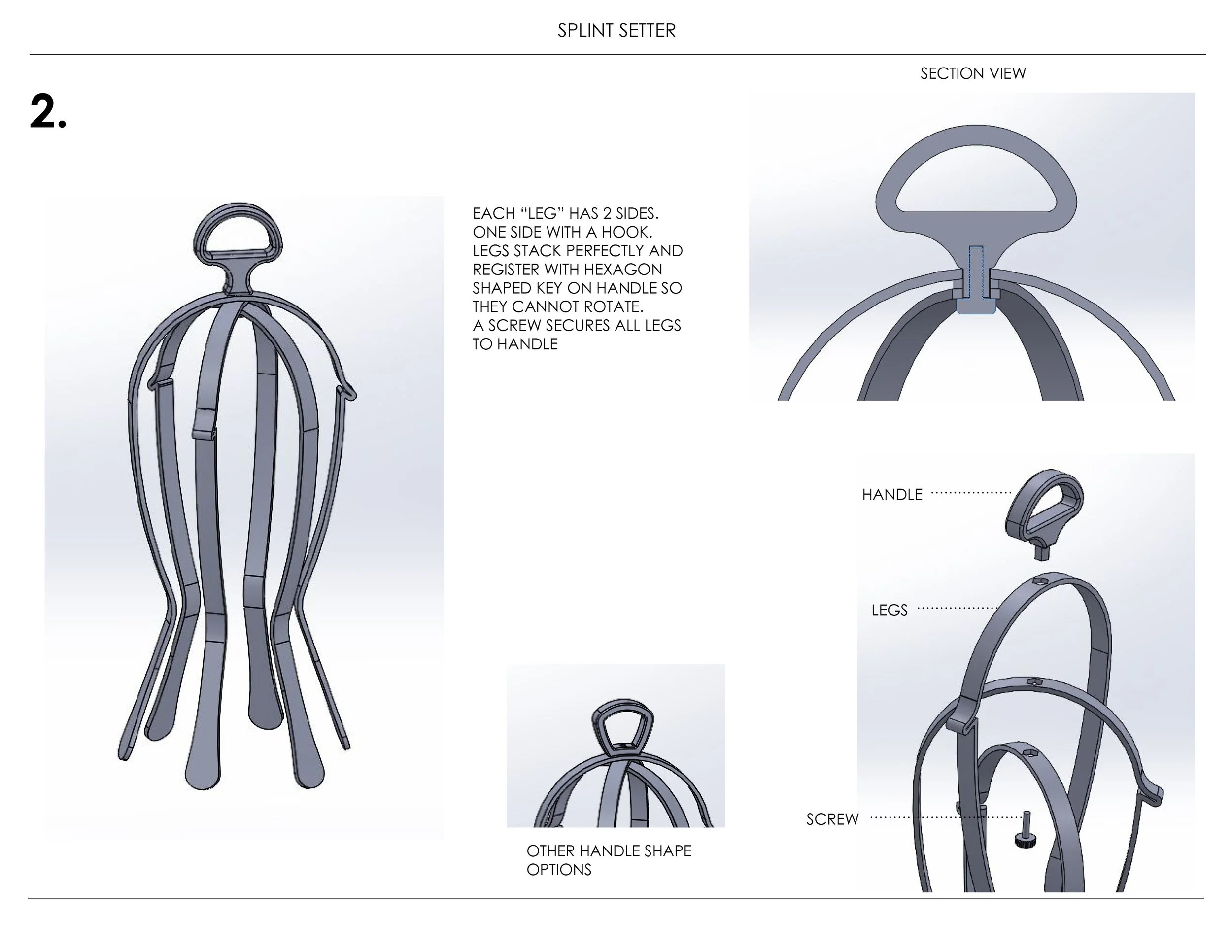

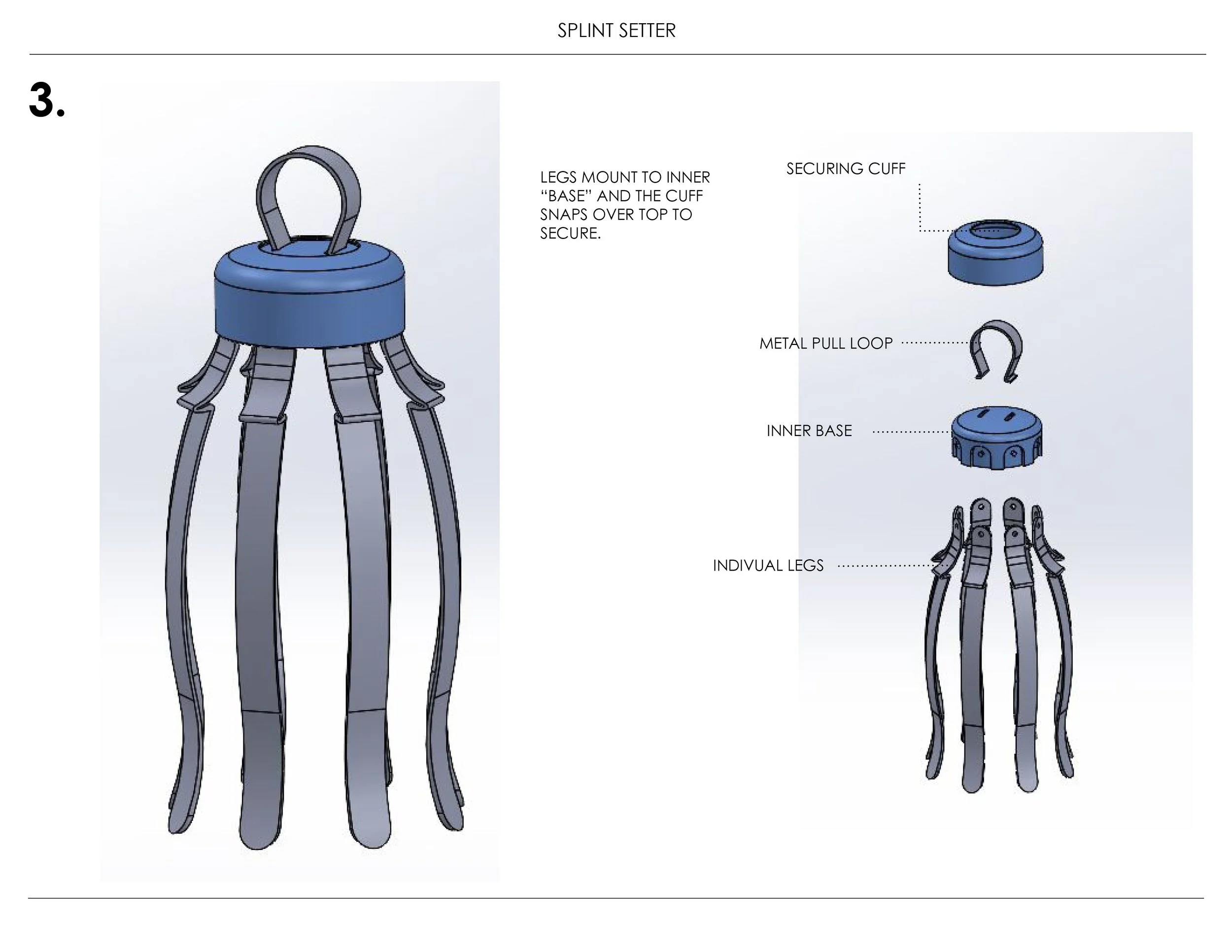

Here are a few CAD concepts that explored the different methods the product could be assembled, as well as varying overall forms. We really had to test each concept out to know how well they perform compared the the original mock-up prototype. We moved forward with producing the concept with the least amount of parts. For manufacturing purposes, option 2 seemed the most cost effective and straight forward.

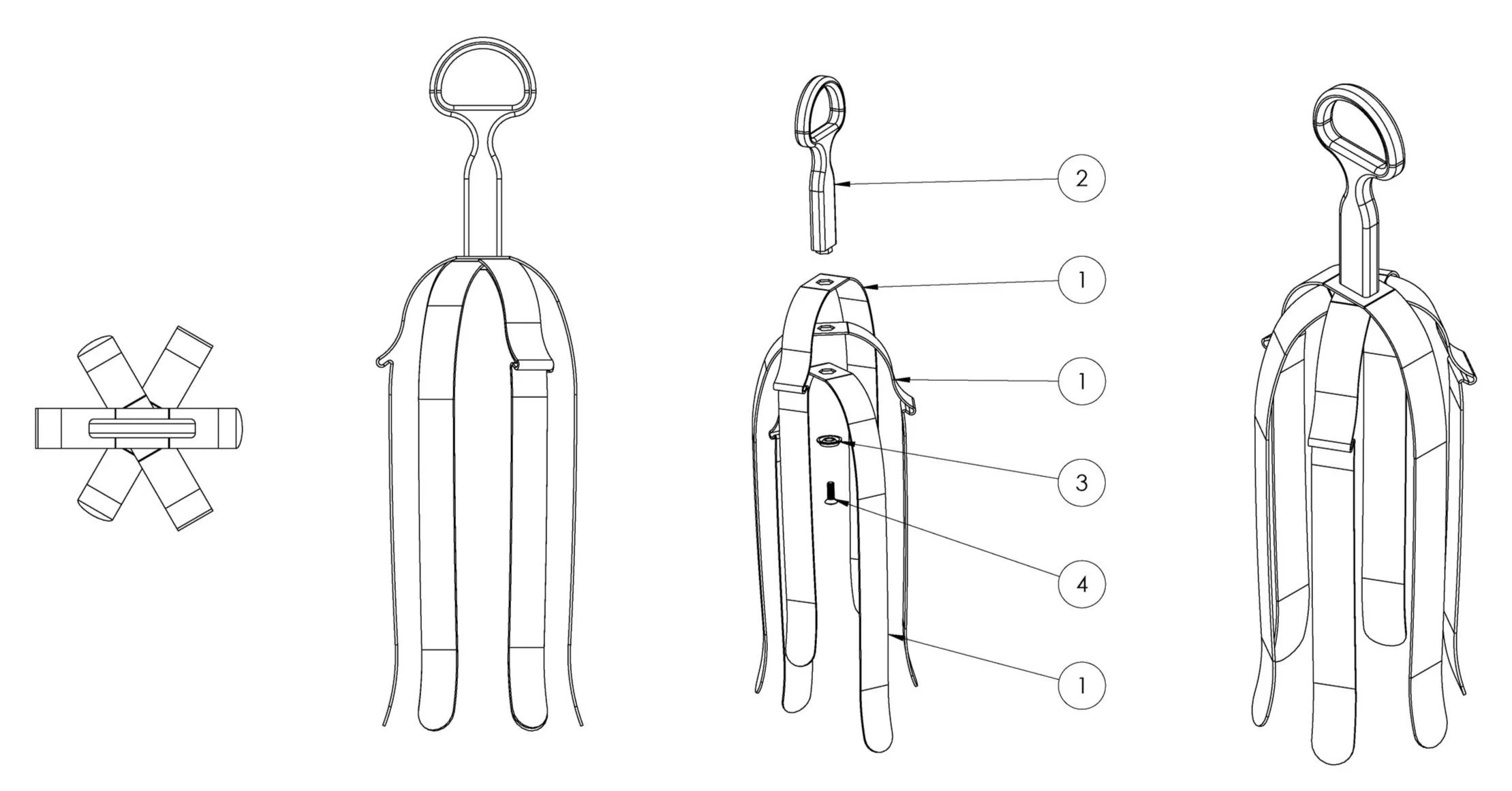

Finalized CAD Drawings

Prototypes were made using laser-cut styrene that was heat formed to create the proper contours, and 3D printed handles . We tested out a few versions of this design to find what worked well and what changes needed to be made. Luckily there were minor changes needed before the product could be made out of its intended material; stainless steel.